How To Operate Concrete Batching Plant

2024.10.16

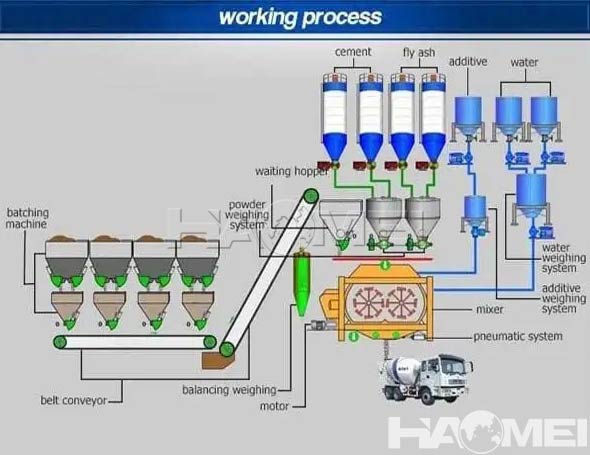

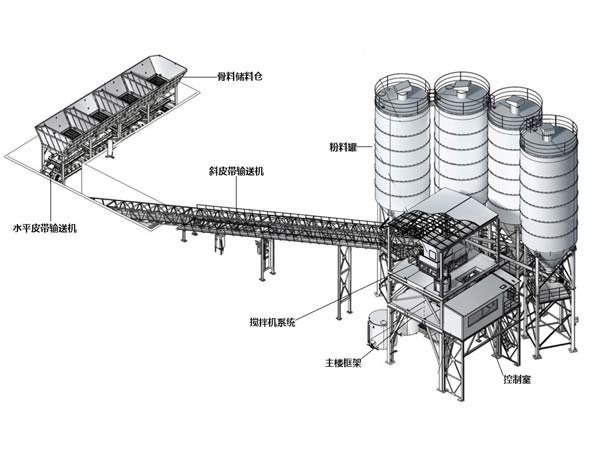

Concrete batching plant is a joint device used for centralized mixing of concrete, which has a high degree of mechanization and automation, and the operation process of concrete batching plant mainly consists of four major steps such as feeding, mixing, transporting and discharging. Its operating procedures are to ensure that the concrete batching plant can operate normally and efficiently, and to ensure that the quality of concrete produced meets the requirements of the important guarantee.

The operation procedure of concrete batching plant generally includes the following steps:

1. Preparation:

- Check the equipment: make sure the mixer, conveying equipment, batching equipment, etc. are running normally.

- Check raw materials: cement, sand, gravel, admixtures and other raw materials should be prepared in accordance with the requirements, and check their quality.

2. Batching:

- Set up the batching system according to the concrete proportion. Input the required proportion of cement, sand, stone and water.

- Start the batching system, automatically or manually weigh and convey each raw material to the concrete mixer in proportion.

3. Mixing:

- Feed the weighed raw materials into the concrete mixer and start the concrete mixer for mixing. The mixing time is set according to the formula and requirements of concrete, usually 2-5 minutes.

- During the mixing process, additives can be added as needed.

4. Discharge:

- After mixing, stop the concrete mixer, open the discharge port and pour the mixed concrete into the transportation vehicle or storage tank.

- Make sure the discharging process is smooth and pay attention to prevent the waste of concrete.

5. Cleaning equipment:

- After each mixing, clean the concrete mixer and batching equipment in time to prevent the concrete from caking and affecting the subsequent production.

6. Record and monitor:

- Record the production data of each batch, including mixing ratio, mixing time, discharge volume, etc., so as to facilitate subsequent analysis and quality control.

- Monitor the production process to ensure that the equipment is running normally and deal with abnormal situations in time.

7. Safety Precautions:

- Operators need to wear good personal protective equipment and pay attention to safe operation.

- Regular maintenance of equipment to ensure that the equipment is in good condition.

The above is the general operation of the concrete batching plant, the specific operation may vary depending on the type of equipment and production requirements.