Concrete Batching Plant Parts & Working Principle

2024.12.25

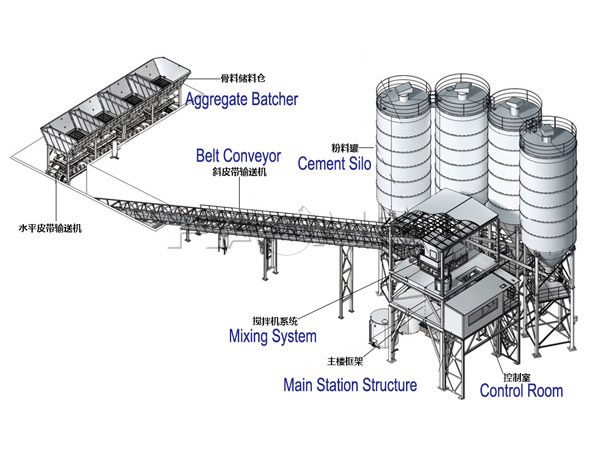

Concrete batching plant mainly consists of several key parts and follows a certain working principle to operate. The main component parts of concrete batching plant include raw material storage system, weighing system, mixing system, control system and discharge system. The raw material storage system is used to store cement, aggregates and water, while the weighing system ensures that the components are accurately weighed in proportion. The mixing system is the heart of the process, mixing the ingredients by means of forced mixing or self-fall mixing. The control system is responsible for monitoring the whole process to ensure the automation and accuracy of the operation. Finally, the mixed concrete is transported to the construction site through the discharging system to realize efficient production.

Main parts of concrete batching plant including:

1.Raw material storage system:

- Cement silo: used for storing cement, usually a cylindrical metal structure with a discharge valve at the bottom.

- Aggregate storage silo: used for storing sand, stone and other aggregates, usually divided into multiple silos for easy classification.

- Water tank: to store water used for mixing.

2.Weighing System:

- Cement Weigher: Used to accurately weigh the required amount of cement.

- Aggregate Weigher: Used for weighing sand and gravel, usually with a variety of weighing hoppers.

- Water Weigher: Used to weigh the required amount of water.

3.Mixing System:

- Mixer: it is the core part of the concrete batching plant, usually there are two kinds of forced and self-fall type. The forced mixer is forced to mix by mixing blades and has good mixing uniformity; the self-falling mixer relies on gravity for mixing.

4.Control system:

- Electric control system: used to control various parts of the concrete batching plant, including weighing, mixing and discharging. Modern concrete batching plant is usually equipped with computer control system to realize automatic operation.

5.Discharge system:

- Discharge hopper: used to convey the mixed concrete to transportation vehicles or other equipment.

- Conveying system: can be belt conveyor, pump, etc., which is used to convey the concrete to the construction site.

The working principle of the concrete batching plant is to use cement as the binder material, and the fly ash, cement, aggregate (sand, stone) and some powder and fine materials will be weighed through the batching machine according to the proportional test. After weighing is completed, the operator starts the sand and stone belt motors to send the weighed ingredients to the metering hopper. Subsequently, additives and water are added and mixed in the mixer. After mixing, the concrete is fed into the opened concrete tanker and conveyed out. The concrete process is as follows:

- Raw material preparation:

According to the concrete recipe, the system automatically or manually selects the required raw materials such as cement, aggregate and water.

- Weighing:

The various raw materials are weighed accurately in the weighing system. After weighing, the system will automatically record the data to ensure the accuracy of the recipe.

- Mixing:

After weighing, the raw materials are fed into the mixer. The mixer starts and mixes the cement, aggregates and water through the mixing blades until a homogeneous concrete is formed.

- Discharging:

After mixing is completed, the concrete is conveyed to the transportation vehicle or directly to the construction site through the discharging system.

- Control & Monitoring:

The whole process is monitored by the control system to ensure the smooth running of each step and to record the production data.

Through the synergistic work of the above components, the concrete batching plant realizes efficient and precise concrete production to meet the needs of different projects.